Plant Information

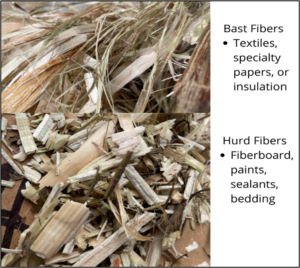

Fiber hemp (Cannabis sativa L.), an annual crop, is grown for bast and hurd fibers. Some are dual-purpose grown for grain and fiber, but the focus of this article is hemp for fiber production. Bast fibers are produced from the outside of the stalk, while hurd fibers are from the interior wood core.

Most of the current fiber hemp varieties are photoperiod sensitive and flower according to day length. Fiber hemp has separate male and female plants, which are typically mixed in a seed bag.

Figure 1. Fiber hemp bast and hurd fibers and different uses of each. Photo Credit Jodie McVane

Planting Information and Rates

Hemp planting rates are typically between 40 to 60 lbs./acre of pure live seed (seed size of 15,000 to 20,000 seeds per lb.). Seeding rates for grain, including for the dual-purpose types, are about half as that of the fiber types. There is no optimum seeding density information established for Texas yet. If planted at a low rate, the stems tend to branch out, which is not desirable for fiber hemp. The stems should be tall and straight with minimal branching for best fiber quality and quantities.

Germination percentage can be variable depending on the seed lot, thus conducting a quick germination test is recommended to develop pure live seed beforehand and adjust the seeding rates accordingly. Fiber hemp is typically planted with a grain drill at a depth of ¼ to ½ inch with soil moisture present. A row-spacing of 7.5 to 10 inches would be ideal to ensure good growth and straight stalks.

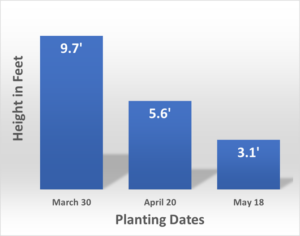

Figure 2. Fiber hemp can grow 6 to 12 feet tall if planted early in College Station, TX. Photo Credit Jodie McVane 2021

Planting Dates

Researchers with Texas A&M AgriLife research is currently investigating the best planting dates and management practices for fiber hemp. The study in central Texas had three planting dates: end of March, Mid-April, and Mid-May. The two years of research study has concluded that an early planting date (late March) is best.

The best planting date for overall biomass and fiber production was the end of March date. This timing fairly corresponds with mid to late corn planting dates in this region. The following chart compares fiber hemp average plant heights produced between the planting dates, which corresponded with biomass yields. The plants with the mid-May planting timing quickly transitioned to flowering.

Figure 3.Fiber hemp height in feet at harvest dates in 2021 growing season.

Figure 4. Fiber hemp plants pollinating early due to later planting date and variety genetics. Photo Credit: Jodie McVane 2021

Variety Selection

Fiber hemp seed can be expensive, and finding a reputable seed dealer with a known track record is important. Prices for the Chinese varieties in 2023 were $3.00 to $4.00 per pound without shipping costs. Recently harvested seed that was properly stored provides better germination results. It is not recommended to use old seed that has been in storage for a while. There is currently no seed coating used in the fiber hemp industry.

Variety selection is key to growing fiber hemp on your farm. Tested varieties in your region should be used and ask Texas A&M Extension employees for assistance with varieties. Much research is still needed in this area, and studies are currently being conducted and planned in Texas. Fiber hemp must also have ≤0.3% THC (within the testing error) to avoid a potential destruct order and loss of crop. To date, Texas A&M AgriLife data suggests that this can be an issue with current Chinese varieties. AgriLife recommends that farmers new to hemp fiber production and growing any variety test on a weekly basis (you do not have to have an official sample for your own test) beginning about 60 days after planting to track THC levels.

Harvest and Retting

Fiber hemp is typically harvested with current haying equipment. A sickle bar mower or hay disc-cutting equipment can be used. Hemp is left in the field to rett. Retting is a process where the stalks come in contact with the soil and microbes work to breakdown and separate the bast from the hurd fibers. Some farmers rake the stalks into rows before collecting them into large bales.

Storage

Hemp bales need to be stored inside buildings if not taken to the decorticator immediately. Decorticators take the bales and process them to separate the fibers. They then connect with manufacturers who will use the fibers in making hemp products.

Weed Control

Weed control studies for hemp are minimal and the Environmental Protection Agency has just recently approved the pre-plant incorporated (PPI) herbicide ethalfluralin (Sonalan HFP, see a label at https://www.cdms.net/ldat/ldDEL015.pdf) for use in hemp.

As of June 2023, AgriLife is not aware of any other approved labels for herbicides, insecticides, fungicides, etc. that may be legally used in hemp production (except some labeled organic products that are unproven and expensive).

Hemp provides excellent weed suppression on its own due to a dense canopy formation. In the experiments conducted in central Texas (College Station), early planted hemp provided much better weed suppression compared to delayed planting dates. Hemp could suffer weed competition if plant growth is slow.

Figure 5. Hemp stalks at harvest and the ability of fiber hemp to suppress weeds. Photo Credit Jodie McVane 2021.

Fitting Fiber Hemp into Your Rotation

Thinking through how hemp will fit into your crop rotation is important, and collaborating with an economist will be wise before making any planting decisions. Do not grow hemp for fiber (or any other purpose) unless you have a signed legally defensible contract. Markets for fiber hemp are still in the developmental stages, and many links in the process need to be connected for farmer profitability. Research has been initiated at College Station to understand hemp-cotton rotation.

Texas Dept. of Agriculture & Hemp Regulations

Hemp production of any kind in Texas requires a license, growing permit, facility permit, and proof of THC ≤0.3% when collected by a licensed hemp sampler and then subsequent chemical analysis within 30 days of harvest. For further information on TDA hemp program requirements, consult https://www.texasagriculture.gov/Regulatory-Programs/Hemp

Take Away Points

- Know what variety works well in your region.

- Know your seed source and economics for your farm.

- Planting date, harvest timing, and storage are critical for yield and quality of fibers.

- Have fun learning how to grow a new crop!

Authors:

Jodie McVane – Texas A&M, College Station – jodiemr@tamu.edu

Calvin Trostle – Texas A&M, Lubbock – ctrostle@ag.tamu.edu

Muthukumar Bagavathiannan – Texas A&M, College Station – muthu@tamu.edu