Morgan McCulloch, Reagan Noland, and Thomas Isakeit

Reniform nematodes, Rotylynchulus reniformis, have become an issue for many cotton producers across Texas. The female microscopic roundworms use specialized stylets (mouthparts) to pierce and embed their heads into roots to syphon nutrients from the plant. This causes above ground stunting, increases the plant’s susceptibility to other stressors, and reduces boll load. Reniform nematodes can remain dormant in the soil for up to two years and have a wide host range. This makes them difficult to manage and requires long-term management plans. Reniform nematodes can begin reproduction in as little as two weeks in the presence of a host. Short life cycles and large population sizes mean that once a population has been introduced into a field, they cannot be easily eradicated. One of the biggest challenges of parasitic nematodes is that they can easily be transferred to new fields and spread within fields via soil movement on field implements, tires, or even shoes. While they can only travel 0 to 1 ½ inches per day on their own power, they can be spread quickly throughout a field with the use of farm implements or other ground disturbing equipment. Taking preventative measures to ensure tillage equipment is sanitized prior to entering a new field is necessary to help slow (or hopefully prevent) the spread of reniform nematodes.

To assess the efficacy of in-field soil sterilization options, a study was conducted to compare the effect of drying soil (vs. fresh) on nematode densities following three different sanitation treatments: 1) no bleach, 2) 10% bleach solution, and a 3) 50% bleach solution. A homogenized sample of soil was collected from a site with a known reniform nematode infestation. For each test, 200 ml of soil was added to an aluminum pie pan and was then saturated with the appropriate treatment. All treatments were replicated 4 times, and were split into fresh and air dried samples. Immediately after treatments were applied, fresh or “wet” samples, were analyzed for nematodes. Air dried treatments were left to dry in the aluminum pie pan for two weeks until they were thoroughly dry, to simulate soil air drying on equipment, and then rehydrated for extraction. All nematode samples were counted using standard methods.

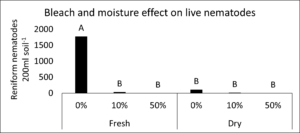

Among bleach treatments, soaking the soil with 10% and 50% bleach reduced live nematodes by an average 98.7% compared to 0% bleach (Table 1). Drying also reduced live nematodes by 93.1% compared to fresh soil (Table 1). An interaction between bleach treatment and soil moisture also occurred, indicating that any addition of bleach and/or air drying significantly reduced live nematodes when compared to fresh treatments without bleach (Figure 1).

Figure 1. Bleach treatment (%) and soil moisture effect on live nematodes

Table 1. Effect of bleach treatment or ultimate soil moisture on live nematodes

| Effect | Soil treatment | Live nematodes 200 cc soil-1 |

| Soil moisture | fresh | 605 A |

| dry | 42 B | |

| Bleach solution | 0% | 945 a |

| 10% | 25 b | |

| 50% | 2 b |

It is important to note that at least a few viable nematodes were extracted following each treatment. None of these methods provided consistent 100% control. Reniform nematodes can survive drying to some extent. The first and most important step to preventing movement of nematodes is thorough cleaning and removal of all soil from equipment. If possible, this should be done on-site where nematode infestation is already known, as washing equipment elsewhere risks depositing new nematodes there. A light-duty pressure washer can be useful to remove tough or dry mud/clay. On planters in particular, be careful around sensors and wiring, and note that soil/mud often accumulates between opener disks and inside the gauge wheels. Based on our experience and this research project, the most effective approach is comprehensive:

- CLEAN – Remove all soil from implements and tires.

- SANITIZE – Use a pump sprayer with a bleach solution to thoroughly wet all surfaces of the implement, especially parts that come into contact with the soil.

- DRY – Allow to dry for as long as possible before movement to a new field.

Despite the often-critical agenda to cover ground and complete field operations in a timely manner, these steps should not be diminished nor ignored. Introduction of soilborne pests to new ground adds a new and permanent challenge to crop production on that land. Negative long-term implications are likely, and include reduced yield potential, possible limitations to crop and rotation options, and increased input costs.